WE CUSTOM BUILD THE FINEST BALERS IN THE WORLD

The McDonald Services family of two ram balers vary in size from the sixty by forty-two inch feed model to the one hundred twenty by fifty-six inch feed model. Of the seventeen different models offered, the "sixty by forty-two" and the "one hundred twenty by fifty-six" models are the most popular.

![]()

|

Our smaller 60" x 42" series balers are able to deliver very high ram face pressures allowing denser bales from many of the materials being baled by recyclers, municipal land fill operators, and waste haulers. Their smaller size allows them to be located in many retail distribution centers and manufacturing facilities.

|

![]()

|

The ability to handle large pieces of waste plus high volume production are two reasons why our 120" x 56" model balers are chosen. Their size alone makes these balers desired by commercial recyclers, municipal land fill operators, and waste haulers.

|

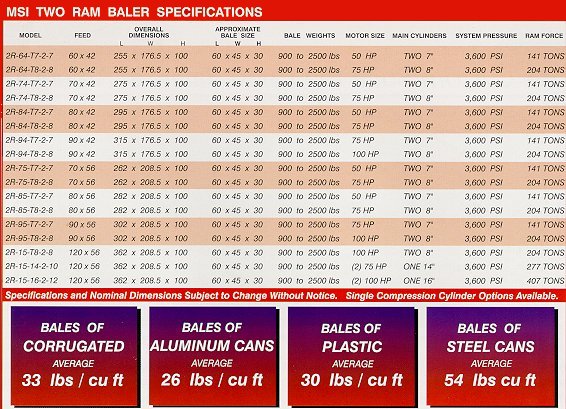

MSI Two Ram Baler Specifications

![]()

|

STANDARD FEATURES

|

ADDITIONAL COST OPTIONS

|

Please call us at 800.468.3454 for pricing information. Thank you for your interest.

© 1997 McDonald Services Incorporated. All Rights Reserved.